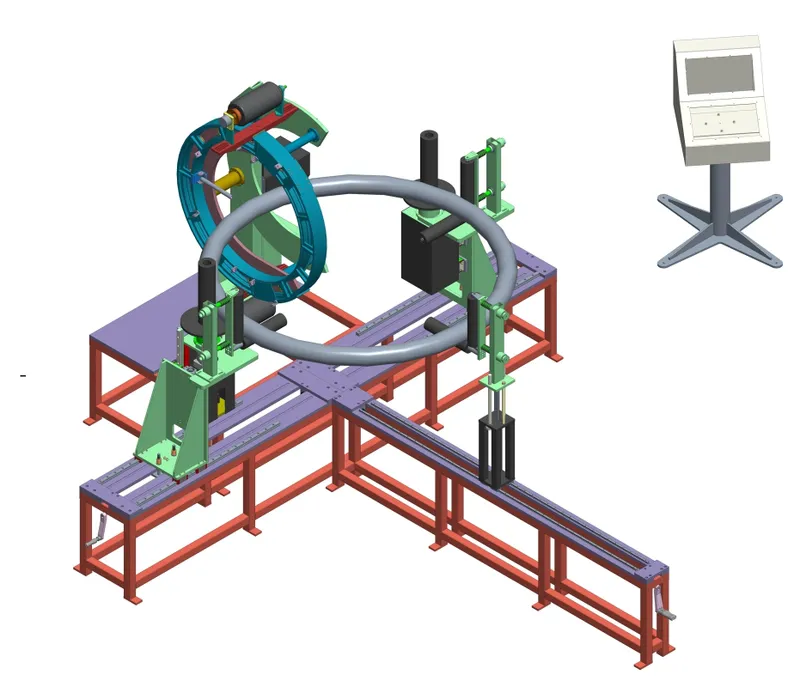

Specialized Equipment for Complex Doughnut-Shaped Composite Forms

Precision engineering for specialized composite forms

Specialized for winding carbon fiber into doughnut-shaped forms

Advanced PLC and HMI for accurate winding parameters

Tailored to meet specific core sizes and winding patterns

Key aspects of our toroidal winding technology

Specialized shapes for advanced applications

A toroidal winding machine is a specialized piece of equipment designed for winding carbon fiber materials into toroidal (doughnut-shaped) forms. Carbon fiber is known for its high strength-to-weight ratio, making it ideal for advanced applications in aerospace, automotive, energy storage, and sports equipment.

Advanced solutions for diverse industries

Manufacturing lightweight structural parts, fuel tanks, and critical components

Production of composite drive shafts, rims, and structural components

Winding of carbon fiber for flywheels in energy storage systems

Creation of high-performance bike frames, tennis rackets, and gear

Why choose our toroidal winding solution

Continuous technological upgrades to enhance functionality and efficiency

Built to meet industry safety standards with comprehensive protection features

Comprehensive after-sales support including training and maintenance

Discover how our toroidal winding machine can revolutionize your production of complex composite forms.