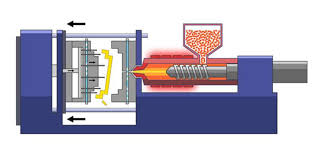

Precision Automation Solutions for Injection Molding

SJ Automations is a full-range supplier of individualized automation solutions for injection molds. Where others reach their limits, our experts closely examine the entire process chain and find innovative ways to tap the concentrated potential of servo technology for you.

With over 12 years of experience in mold making and automation, our team develops reliable and precise applications tailored to each process.

The unthreading of threads by means of rotary and linear motion is used in injection molding production, from the Luer-Lock adapter to the sealing cap. With the help of servo-electric components and systems, you can accelerate the decisive steps in your process and make them more efficient and safer.

Numerous competencies are required for the complete integration of servo drives in injection molds, from extensive planning to assembly

The profound knowledge gained from more than 12 years of experience in the fields of mold making and automation enables our team to develop reliable and precise applications.

We provide individually adapted solutions for each process and fully realized from a single source. Servo technology scores with speed, precision and 100% controllability.

Over 12 years of experience help us recognize the specifics of your industry and quickly develop the optimal solution for your injection molding challenges.

Our comprehensive process ensures maximum performance and process safety

The calculation of different influencing parameters and process forces via software forms the secure basis of our designs.

Materials, tolerances and risks are analyzed comprehensively before projects move from CAD to engineering.

All stations on the way to the injection molding machine are geared towards a ready-to-use result.

Final testing ensures maximum performance and process safety for your production environment.

Injection molding manufacturers share the same requirements across industries for efficient and safe production

In the medical and pharmaceutical sector, clean and burr-free processing as well as fault-free functionality are decisive prerequisites. Our technology supports the industry with the highest precision and process accuracy and can be easily integrated into cleanroom production environments.

The world of packaging and consumer goods requires efficient production with the shortest cycle times, maximum availability and high output. Our SJ Automation solutions optimise injection moulds for the production of caps & closures, and create the perfect conditions for maintaining 100% control in fast cycles.

In the electrical and automotive industries, injection moldings applications reach a high degree of complexity and the quality requirements are high. Our systems offer optimal conditions for significantly increasing mould safety and safely designing complex processes through precise, reliable and repeatable movements.

Advantages of our servo control solutions for injection molds

Accelerate production cycles with servo-electric components

Maintain 100% control over complex movements

Ensure operator safety with controlled movements

Repeatable, consistent performance cycle after cycle

Discover how our servo control solutions can transform your production efficiency and precision.