Efficient and Reliable Component Extraction Technology

Optimizing extraction processes across industries

Your premier provider of cutting-edge Hydraulic Extractor solutions designed to streamline and optimize extraction processes across various industries. We specialize in delivering robust equipment that ensures efficiency, reliability, and safety in component extraction.

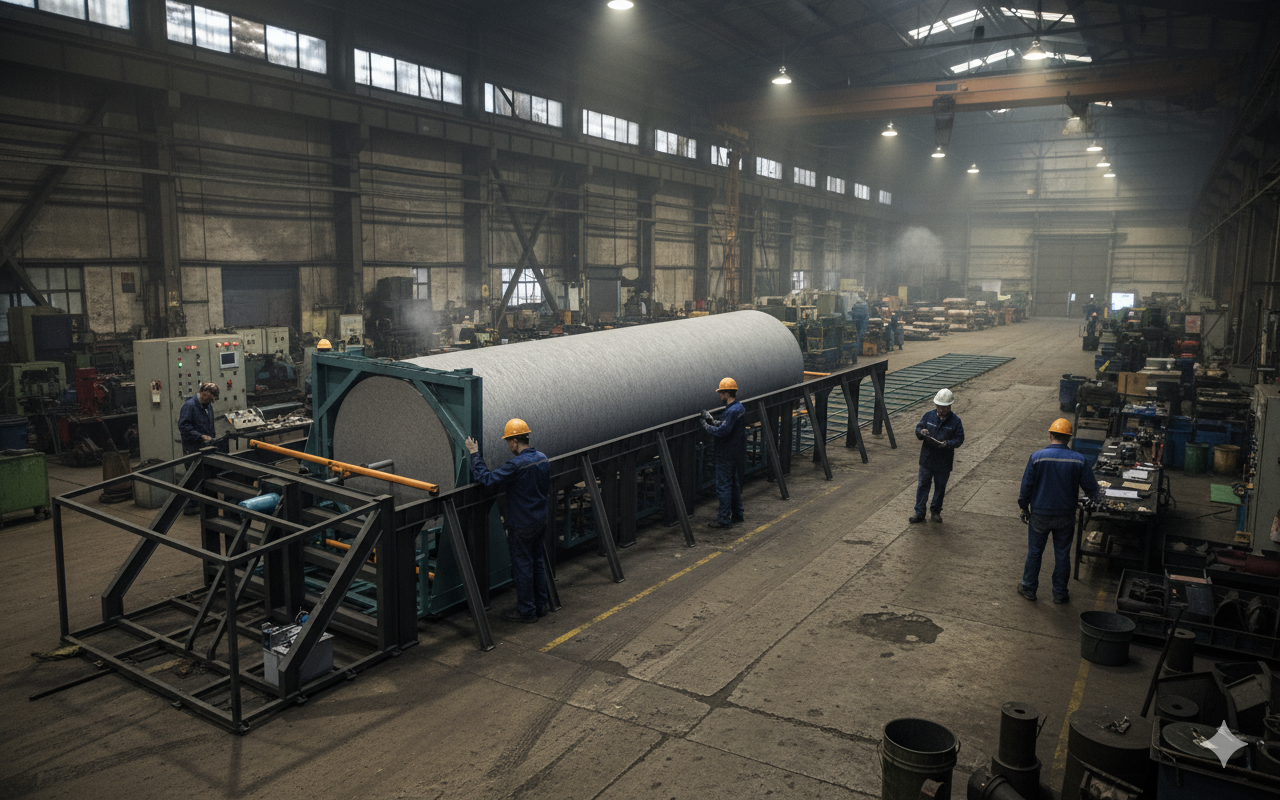

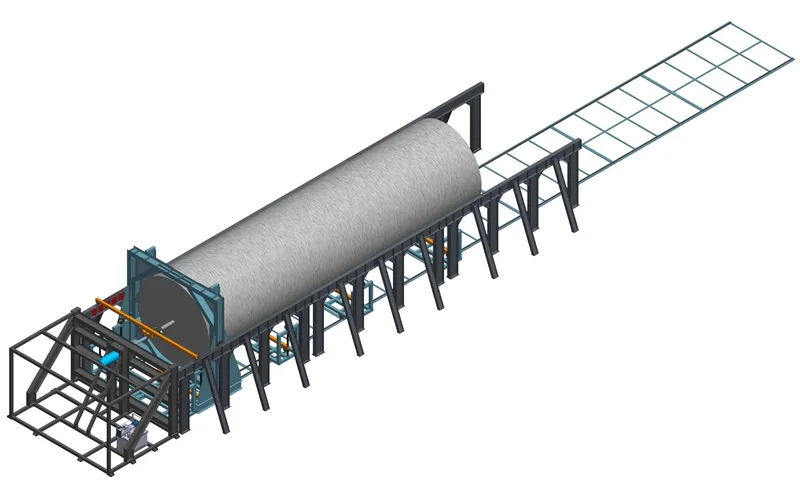

Our hydraulic extractors are engineered with advanced technology to deliver superior performance in demanding industrial environments.

In composite manufacturing, mandrels are used as temporary forms around which composite materials such as carbon fiber or fiberglass are laid up and cured. Once the composite material has cured and formed around the mandrel, the mandrel must be removed to release the final part.

Our hydraulic extractors are utilized across multiple industries for various extraction applications.

How our hydraulic extractors streamline composite manufacturing

Mandrels are prepared as temporary forms for composite layup. Composite materials are laid around the mandrel and cured to form the final part.

The composite part with mandrel is positioned in the hydraulic extractor. The extractor's gripping mechanism securely holds the mandrel.

The hydraulic system applies controlled force to extract the mandrel smoothly and evenly from the composite part without causing damage.

The composite part is released once the mandrel is fully extracted, maintaining dimensional accuracy and structural integrity.

Advantages of our hydraulic extractor solutions

Streamlined extraction reduces cycle times and increases throughput

Accurate force application prevents damage to composite parts

Built-in safety features protect operators from hazards

Adaptable to various mandrel types and sizes

Discover how our hydraulic extractors can enhance your manufacturing efficiency and safety.