Precision Solutions for High-Performance Composite Structures

Advanced techniques for creating superior composite structures

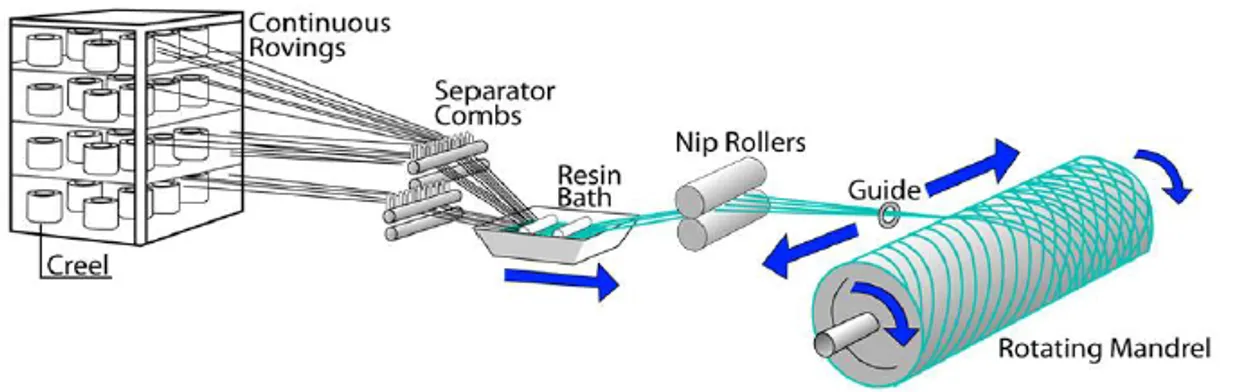

Filaments are wound under tension over a rotating mandrel. The mandrel rotates by head stock (X axis) while a delivery eye on a carriage axis (Y axis) traverses horizontally.

Fibers are laid down in precise patterns and angles relative to the rotation axis. The most common filaments are glass or carbon, impregnated with resin by passing through a bath.

Once the mandrel is completely covered, the resin system is cured. The mandrel is often autoclaved or heated in an oven to complete the curing process.

After curing, the mandrel is removed, leaving a hollow final product with exceptional strength-to-weight ratio and dimensional stability.

Specialized solutions for advanced composite manufacturing

We design and manufacture state-of-the-art filament winding machines tailored to your specific application requirements, ensuring optimal performance and reliability.

Utilizing advanced software and control systems, we optimize the filament winding process to enhance productivity and achieve consistent quality outcomes.

We work with a wide range of composite materials, including carbon fiber, fiberglass, and aramid fibers, offering expertise in material selection and compatibility.

From design to installation and support, we provide comprehensive solutions. We offer international shipping with logistics coordination and customs handling.

See how our advanced winding technology creates precision composite structures

Advantages of our filament winding solutions

Create components with exceptional strength-to-weight ratios

Accurate fiber placement for consistent, high-quality products

Optimized winding patterns reduce material waste and cycle times

International shipping with expert logistics coordination

Discover how our filament winding solutions can transform your production capabilities.